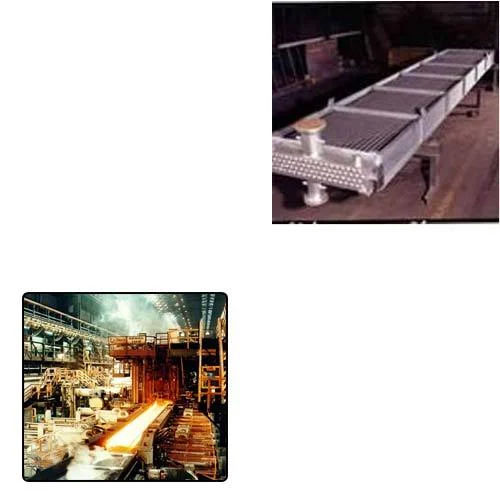

Industrial Air Cooled Heat Exchanger

Product Details:

- Thickness 3 mm (tube wall)

- Temperature High-temperature

- Number of Pipe 48 tubes

- Air Volume 9000 m3/h

- Max Pressure 25 bar

- Diameter 32 mm (tube outer diameter)

- Max. Capacity 15,000 kcal/h

- Click to View more

Industrial Air Cooled Heat Exchanger Price And Quantity

- 90000 INR/Unit

- 10 Unit

- Air Cooled

- 130 m2

- ASME / TEMA

- Axial Impeller Fan

- Copper/Aluminum/SS304

- 3

- Crossflow

- Horizontal

- Less than 78 dB

- High

Industrial Air Cooled Heat Exchanger Product Specifications

- 15,000 kcal/h

- Approx. 450 kg

- 7.5 kW

- 9000 m3/h

- up to 25 bar

- 25 bar

- 32 mm (tube outer diameter)

- 2400 mm x 950 mm x 1300 mm

- Finned Tube and Header

- 3500 LPH

- High-temperature

- Industrial

- 48 tubes

- 415 V

- 3 mm (tube wall)

- New

- Air Cooled

- 130 m2

- ASME / TEMA

- Axial Impeller Fan

- Copper/Aluminum/SS304

- 3

- Crossflow

- Horizontal

- Less than 78 dB

- High

Industrial Air Cooled Heat Exchanger Trade Information

- 1000 Unit Per Month

- 10 Days

- All India

Product Description

Owing to our expertise in this domain, we offer Industrial Air-Cooled Heat Exchanger that is made by using quality tested silk fabric with the help of advanced technologies. This item is widely utilized in the chemical, oil, gas, process and power generation fields for cooling or condensing process streams with ambient air. It is demanded in the market because of its good quality and highly durable in nature. The entire range of provided items is tested on the various quality parameters before final dispatch. The delivery of this Industrial Air-Cooled Heat Exchanger is done by us within the promised time frame.

Product details

| Medium Used | Air |

| Usage/Application | Hydraulic and Industrial Process |

| Type | Air-Cooled |

| Voltage | NA |

| Material | INDUSTRIAL AR COOLED |

| Brand | IR |

Advanced Design and Materials

Engineered for reliability, this industrial air cooled heat exchanger incorporates a robust finned tube and header structure, with tube options in copper, aluminum, or SS304. The 3 mm tube wall thickness and high corrosion resistance make it an ideal solution for challenging industrial environments.

Effective Heat Transfer Solution

Utilizing a crossflow heat transfer method and an expansive 130 m2 fin surface area, this heat exchanger assures efficient cooling for liquids at high temperatures. Three axial impeller fans work synergistically to deliver high air volume with minimized noise, enhancing operational comfort and system performance.

Industrial-Grade Performance

With an emphasis on durability, the unit complies with ASME and TEMA standards. It operates reliably under pressures up to 25 bar and high flow rates, making it suitable for mission-critical applications in industries needing effective air-cooled solutions. The horizontal installation and compact dimensions facilitate easy setup and integration.

FAQs of Industrial Air Cooled Heat Exchanger:

Q: How does the air cooled heat exchanger operate in an industrial environment?

A: The air cooled heat exchanger works by transferring heat from process fluids inside finned tubes to ambient air, using three axial impeller fans to maximize airflow. Its crossflow design enhances heat dissipation, making it adept for high-temperature industrial processes.Q: What tube materials are available, and how do they benefit different applications?

A: This unit offers tubes made from copper, aluminum, or SS304. Copper provides excellent thermal conductivity, aluminum ensures lightweight yet efficient performance, and SS304 is known for its durability and high corrosion resistance, making the exchanger versatile for varied industrial needs.Q: When is it ideal to use a horizontal air cooled heat exchanger?

A: A horizontal installation is best suited when space constraints or process layout demand easy access and efficient airflow. It allows for stable support and even distribution of air across all 48 tubes, optimizing the heat exchange process.Q: Where can this heat exchanger be installed within a facility?

A: It is suitable for installation in areas with adequate ventilation and structural support for its 450 kg weight. Proper clearances around the 2400 mm x 950 mm x 1300 mm footprint ensure optimal air intake and exhaust, contributing to its efficient operation.Q: What processes commonly use this heat exchanger?

A: The unit is commonly deployed in industries requiring reliable cooling of high-temperature fluids, such as power generation, chemical plants, oil and gas processing, and manufacturing. Its ability to handle flow rates up to 3500 LPH and resist corrosion makes it ideal for demanding environments.Q: How is the unit maintained to ensure long-term performance?

A: Routine inspection of the finned tubes, header, and fans is recommended. Cleaning the fins and ensuring fans are debris-free helps sustain thermal efficiency. Adherence to ASME/TEMA standards simplifies scheduled maintenance protocols.Q: What are the main operational benefits of this heat exchanger?

A: Key advantages include efficient heat transfer, high corrosion resistance, compliance with international standards, quiet operation (less than 78 dB), and adaptability to high-pressure systems (up to 25 bar). Its energy-efficient fans and durable construction enhance reliability and reduce operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Heat Exchanger' category

|

BND ENGINEERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |