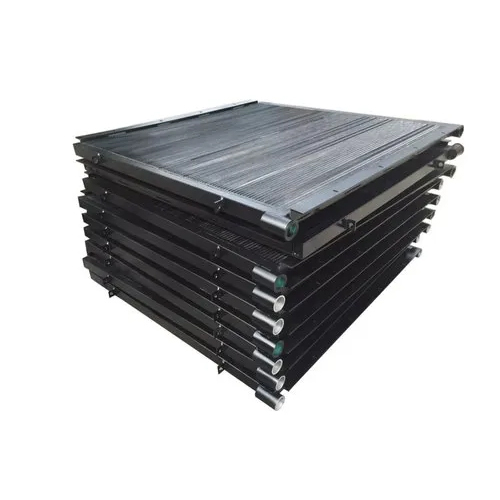

Coupling Shims

Product Details:

- Drive Type Flexible

- Control System Manual

- Noise Level Low

- Weight Lightweight

- Configuration Flat

- Power Source Ac Power

- Silent Yes

- Click to View more

Coupling Shims Price And Quantity

- 500 INR/Unit

- 50 Unit

- Machinery, Motor Shafts

- Rectangular

- High

- Coupling Alignment

- Stainless Steel

- 0.05 mm to 1.00 mm

- Reusable & Durable

- Standard & Custom Sizes Available

- Smooth

- Box

Coupling Shims Product Specifications

- Flat

- Mechanical

- Manual

- Lubricated

- Lightweight

- Low

- Yes

- Flexible

- Ac Power

- Machinery, Motor Shafts

- Rectangular

- High

- Coupling Alignment

- Stainless Steel

- 0.05 mm to 1.00 mm

- Reusable & Durable

- Standard & Custom Sizes Available

- Smooth

- Box

Coupling Shims Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 1000 Unit Per Month

- 10 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

We as a company serving our respected clients by manufacturing and supplying excellent qualityCoupling Shims to our clients. It is made by using top notch quality required materials with the help of cutting edge techniques and tools under the supervision of our experts. This item is extensively used in steel mills, chemicals plant, paper mills, refineries and power plant for preventing leakage between two coupling. It works by filling small gaps or spaces between objects. All our offered items are properly checked on well-defined parameters prior to final delivery to ensure that our clients get a flawless range. To cater to varying needs of our valued patrons, we offer this Coupling Shims in different technical specifications and that too at reasonable rates.

Reliable Performance for Machinery Alignment

Our coupling shims deliver precise alignment for motor shafts and machinery couplings. Crafted from high-grade stainless steel, they offer excellent durability and a smooth finish to minimize friction, ensuring each maintenance or installation task is completed efficiently. The high corrosion resistance extends service life even in demanding environments.

Versatile Size Options for Every Need

Choose from a spectrum of standard and custom sizes to perfectly match your alignment requirements. Whether working with small motors or larger mechanical assemblies, these rectangular shims offer flexibility for diverse industrial applications. The provided packaging ensures your shims remain organized and protected from damage.

Effortless Installation and Reusability

Featuring a lightweight and flat design, our coupling shims are easy to handle and install. Their robust stainless steel construction, coupled with the ability to withstand repeated usage, makes them a cost-effective solution. The smooth and lubricated surfaces further simplify installation while maintaining silent and stable operation.

FAQs of Coupling Shims:

Q: How are stainless steel coupling shims used in machinery alignment?

A: Stainless steel coupling shims are inserted between coupling faces or beneath machinery bases to fine-tune the alignment of motor shafts and couplings. Their precise thicknesses help achieve accurate alignment, reducing vibration and wear in rotating equipment.Q: What are the benefits of using these shims for machinery applications?

A: The main advantages include high durability, excellent corrosion resistance, and a smooth finish for efficient handling. Their reusability and lightweight design ensure easy installation and long-term cost savings, while their silent operation improves workplace comfort.Q: When should I use coupling shims in my machinery setup?

A: Coupling shims should be used whenever precise alignment between machine parts or motor shafts is critical to prevent excessive wear, noise, or mechanical failures. They are essential during installation, equipment repair, or routine maintenance.Q: Where can these shims be applied outside of motor shaft alignment?

A: Besides aligning motor shafts, these shims are suitable for correcting misalignments in various machinery setups, pumps, compressors, and any application requiring tight tolerance adjustments between mechanical components.Q: What is the process for selecting the right shim size and thickness?

A: Determine the alignment offset or gap by measuring the machinery setup. Select the shim size (standard or custom) and thickness that matches the required adjustment, then insert as needed to achieve proper alignment. Multiple shims can be stacked for finer accuracy.Q: How does the smooth, lubricated finish contribute to performance?

A: A smooth, lubricated surface reduces friction during installation and removal, prevents damage to machinery contact surfaces, and helps maintain a silent, vibration-free operation. It also aids in achieving precise adjustments with minimal effort.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Compressor Parts' category

|

BND ENGINEERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |