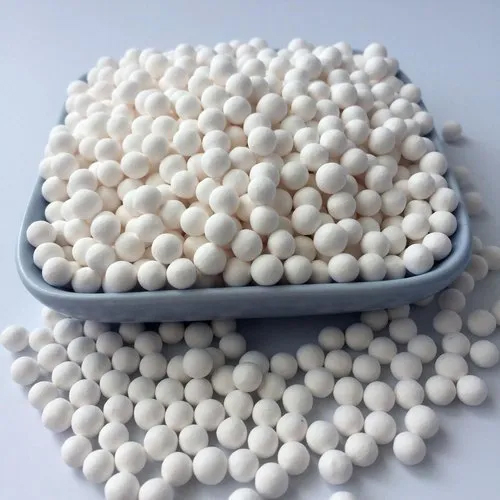

Activated Alumina

Product Details:

- Weight Granules / Beads, 25 - 50 Kg Bags

- Power Source Ac Power

- Silent Yes

- Lubrication Type Lubricated

- Click to View more

Activated Alumina Price And Quantity

- 100 Kilograms

- 1000 INR/Kilograms

- White Spherical Beads

- Drying of Air, Gas & Liquids

- 18% (Maximum)

- 0.4 - 0.5 cm³/g

- 1344-28-1

- 99%

- 0.65 - 0.75 g/cm³

- 350-400 m²/g

- 2-5 mm

- 170 - 180°C

- Al2O3

- <0.2%

Activated Alumina Product Specifications

- Ac Power

- Lubricated

- Yes

- Granules / Beads, 25 - 50 Kg Bags

- White Spherical Beads

- Drying of Air, Gas & Liquids

- 18% (Maximum)

- 0.4 - 0.5 cm³/g

- 1344-28-1

- 99%

- 0.65 - 0.75 g/cm³

- 350-400 m²/g

- 2-5 mm

- 170 - 180°C

- Al2O3

- <0.2%

Activated Alumina Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 1000 Kilograms Per Month

- 10 Days

- Yes

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

We are a reputed and well-known company engaged in manufacturing and supplying excellent qualityActivated Alumina to our clients. It is made by using qualitative top notch quality materials with the assistance of cutting edge techniques under the visionary of professionals. This machine is mainly utilized as a selective adsorbent in polyethylene production and hydrogen peroxide production. We have a team of adroit professionals who guides and supervises workers at every stage of production to ensure that our locks comply with international quality standards. We make this Activated Aluminain different models and technical specifications as per requirements.

Product details

|

Country of Origin |

Made in India |

|

Bead Size |

1-3 mm |

|

Dew Point |

40 deg C |

|

Form |

Spherical Balls |

|

Free Moisture(%) |

less than 2% |

|

Packaging Detail |

25 Kg Poly Bag |

|

Purity |

99% |

|

Solubility in water |

Yes |

|

Usage/Application |

drying of organic liquids,water purification |

Optimized Drying Performance

Activated Alumina delivers reliable drying for air, gases, and various liquids due to its advanced porous structure and high surface area. Its moisture adsorption capability of up to 18% enables efficient water removal, making it ideal for industries where air and gas streams must remain dry and contaminant-free. The beads maintain their integrity under rigorous process conditions, ensuring consistent performance.

Simple Regeneration and Longevity

This material stands out for its ease of regeneration. By applying heat at 170180C, the beads can be restored to their original adsorption capacity, offering a cost-effective solution for long-term operation. With a low attrition loss and robust chemical composition, Activated Alumina supports extended usage cycles while minimizing maintenance needs.

FAQs of Activated Alumina:

Q: How is Activated Alumina used to dry air, gas, and liquids in industrial settings?

A: Activated Alumina is employed as a desiccant in various drying systems. Its high porosity and surface area allow it to adsorb moisture from air, gases, and liquids as they pass through a packed bed of beads, resulting in dry output essential for many industrial applications.Q: What is the regeneration process for Activated Alumina and when should it be performed?

A: Regeneration involves heating the Activated Alumina beads typically at temperatures between 170180C to drive off absorbed moisture, restoring their adsorption capacity. This process should be performed once the beads become saturated, as indicated by a decrease in drying efficiency.Q: Where can Activated Alumina be effectively applied in industry?

A: Activated Alumina is widely used in air dryers, gas purification plants, liquid dehydration systems, and petrochemical processing. Its performance makes it a preferred choice for sectors requiring high moisture removal and stable operational output.Q: What benefits does using high-purity Activated Alumina offer?

A: With 99% purity and strong resistance to physical and chemical degradation, Activated Alumina ensures consistent adsorption efficiency, minimal product loss due to attrition, and safe handling due to its inert nature.Q: How does the specific surface area and pore volume enhance moisture adsorption?

A: The large surface area (350400 m/g) and substantial pore volume (0.40.5 cm/g) provide ample sites for water molecules to adhere, resulting in efficient moisture removal from the treated stream.Q: What is the advantage of the spherical bead form and available packaging?

A: The white spherical bead form promotes uniform packing, reducing pressure drop and enhancing contact efficiency. The product is conveniently supplied in 2550 kg bags for straightforward handling and storage at industrial facilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Compressor Parts' category

|

BND ENGINEERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |